I think nearly every sailing blog has a post (or two) on the topic of head repair. When living on land I take for granted that when I flush the toilette my waste simply goes away. I only have to think about it when the water/sewer bill comes due (or when I have to dig up the tank to be pumped.) Aboard it’s probably a weekly issue and if the head is acting up… Ain’t nobody happy.

Anyway, my head had been leaking for a few months and it was finally time to sit down and see what the problem was. I have a Raritan PHII manual pump marine toilette and I’ve heard good things about it. It seemed pretty easy to disassemble. In preparation I also bought the rebuild kit. So I got started.

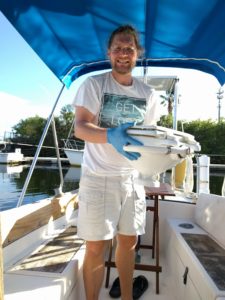

After completely disassembling the unit Sara and I cleaned all the parts and installed all the new o-rings and seals from the rebuild kit.

While cleaning the pump housing I discovered the crack which was the cause of the leak.

I called around but no one carried the pump housing. Ordering one would take at least two days so I decided to use some 3M 4000 adhesive sealant that I had in my toolbox. I applied the sealant on the inside and outside of the pump.

Finally I assembled everything and tested the pump.

Sure enough it worked like a charm. Now we’ll wait to see how long my sealant hack works. I should probably order the pump housing now to have it if and when the sealant breaks down. Here’s hoping it lasts a good long time!